From the hair curler to DNA blood analysis – the Wirthwein Medical story.

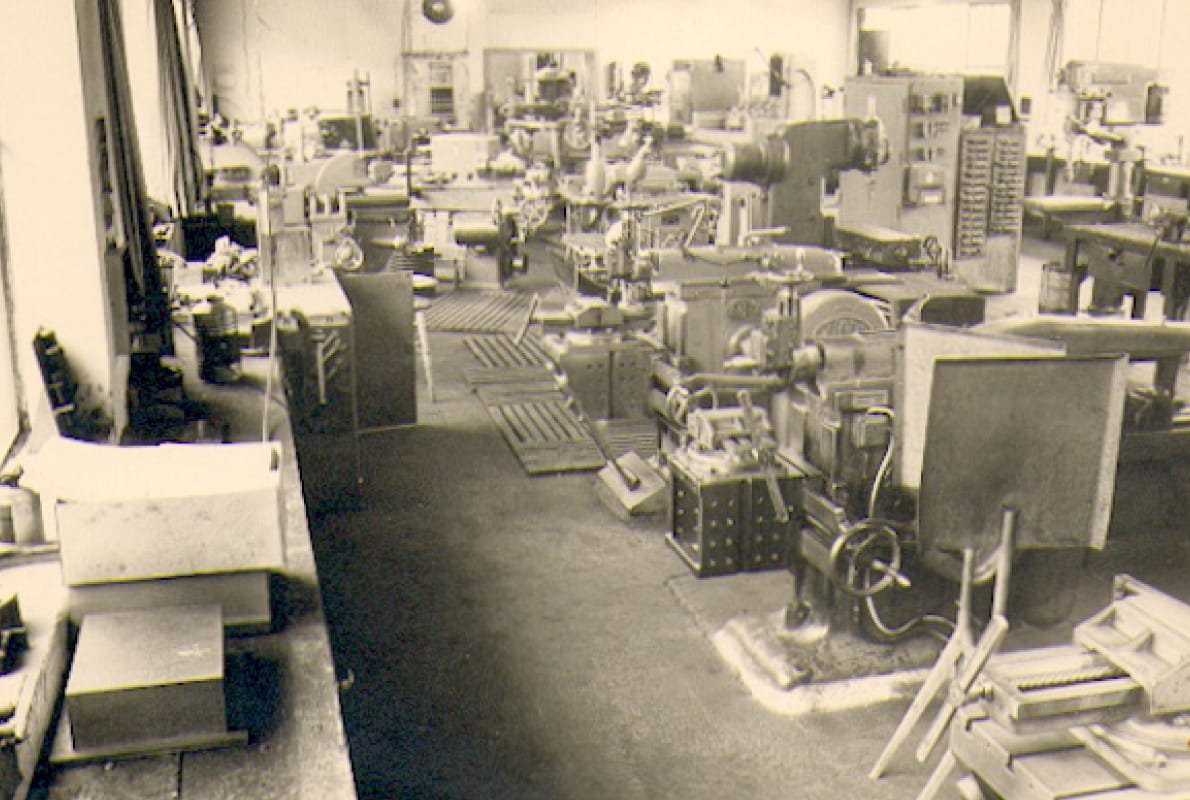

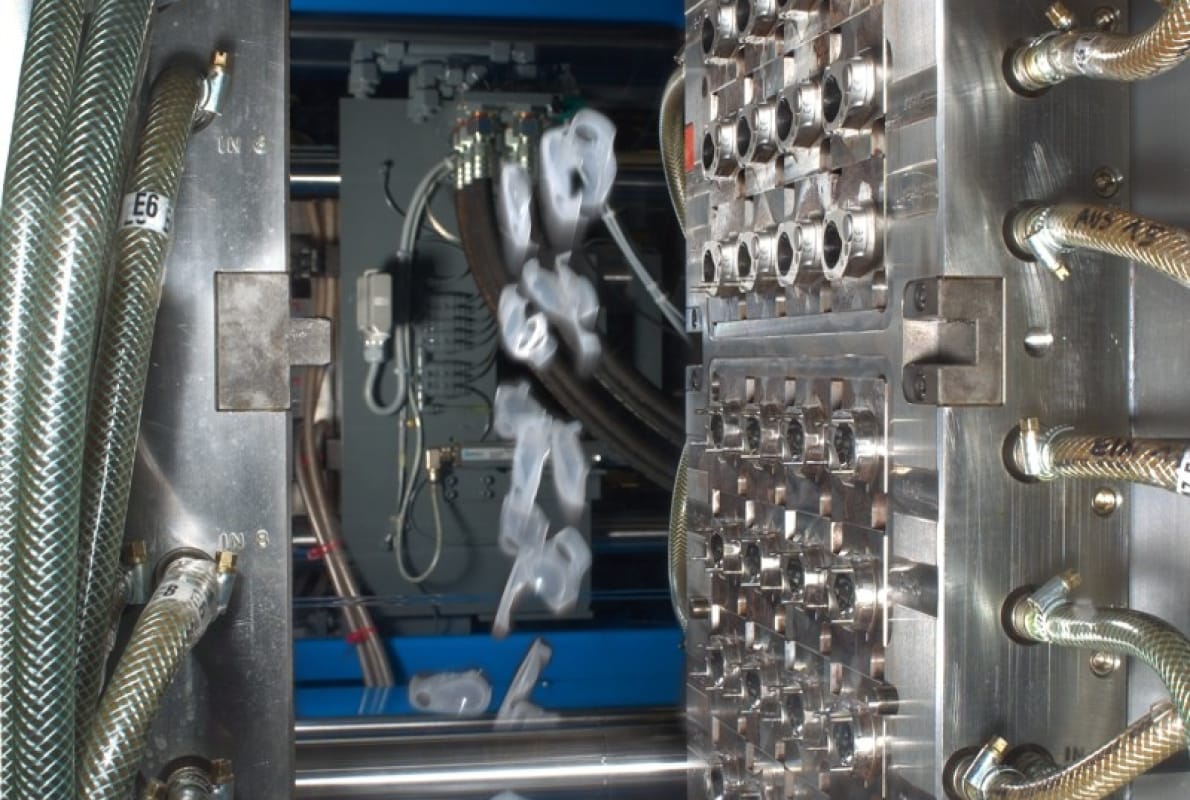

Our company history starts in Mühltal in Hessen in the post-war period as a small one man business in the mainly manual manufacture of molding tools for the furniture industry. Today, we are one of the leading quality system suppliers for precision, highly automated clean room articles with more than 330 employees on a total area of more than 55,000 m2. Over 70 years in which we had enough time to jointly expand and further develop our competences, technologies and materials for our customers.

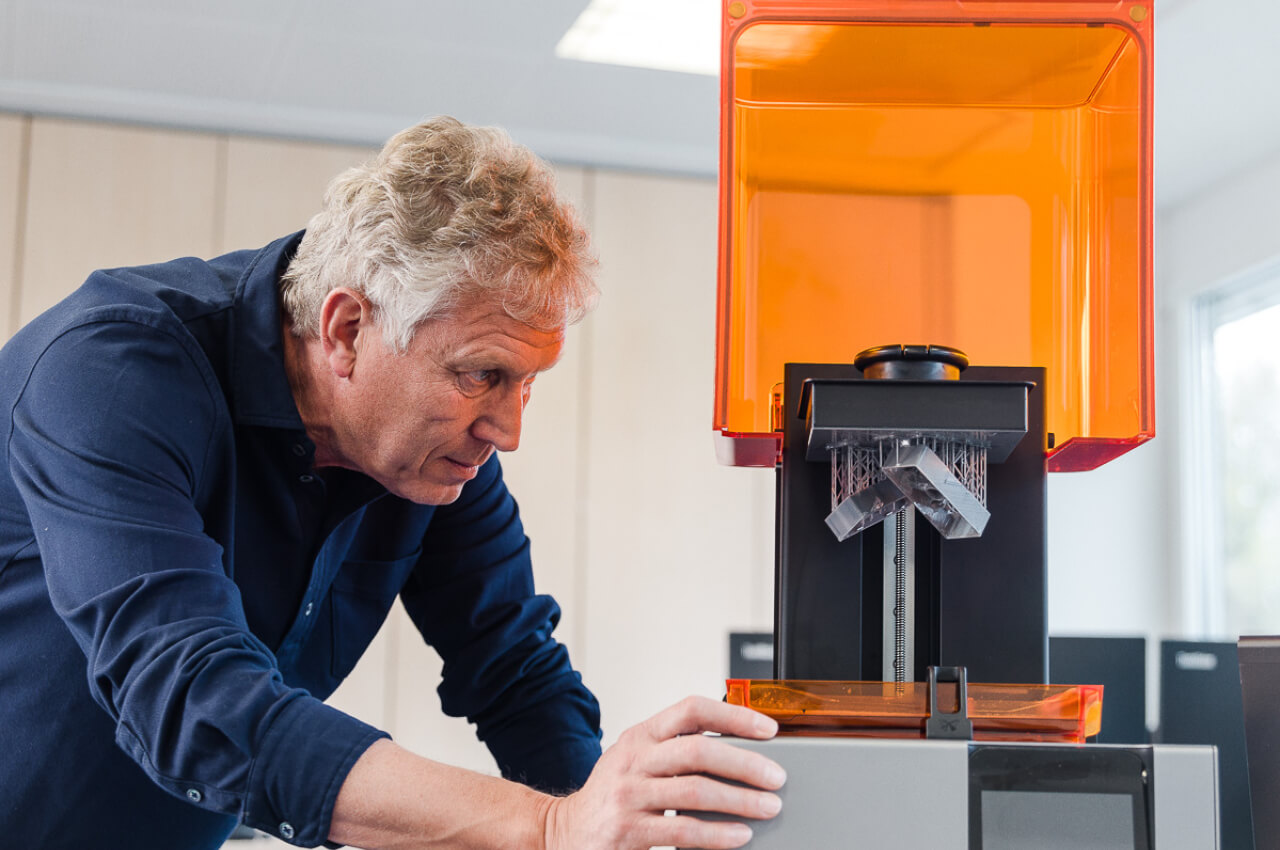

1946 – Foundation by Fritz Albert Riegler 1949 – First hair curler for Goldwell 1954 – The groundbreaking 1958 – Self-made injection molding machines 1960 – Numerous patent applications 1962 – Further production plant 1968 – Change of generations from 1968 – Packagings for Philips Eindhoven 1970 – Focus on packaging 1975 – Detergent and care products industry 1987 – Exit from CFC production 1992 – Start into medical technology 1992 – Great challenge 1994 – Move to the new plant 1996 – 50 years anniversary 2004 – Inauguration of the administrative building 2005 – Takeover by the Wirthwein family 2007 – New center for medical technology 2010 – Expansion of the board of directors 2012 – The company is growing 2016 – Dr. Thomas Jakob becomes a new member of the board of directors 2016 – 70 years anniversary 2017 – New technologies and competencies 2018 – Riegler continues growth course 2019 – Investments & Digitalization 2020 – Change of name to Wirthwein Medical Today – The success story continues